- August 28th, 2010, 11:59 pm#258221

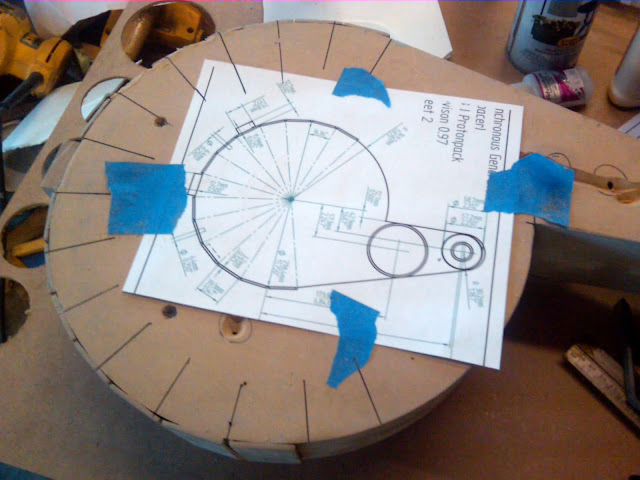

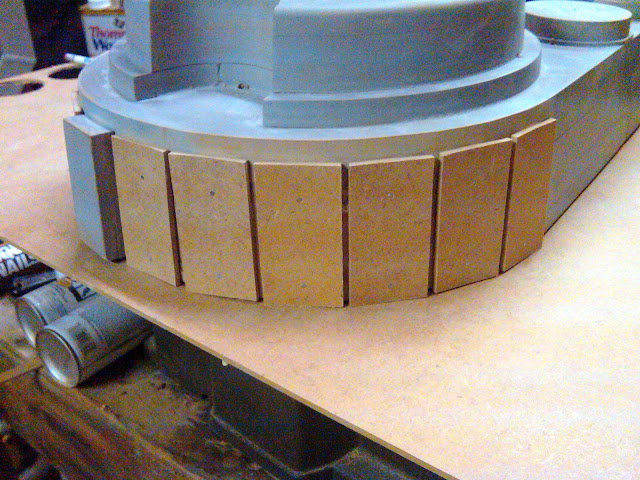

I'm new to the gbfans and Ghostbusters in general but I've been doing prop building semi-professionally for about 6 years now. I've started working on molds for a Vacuum formed pack. I think I can get better results than most of the vacformed packs I have seen. I spent the day working on a few of the key parts.

I'll post updates as they come.

I'll post updates as they come.